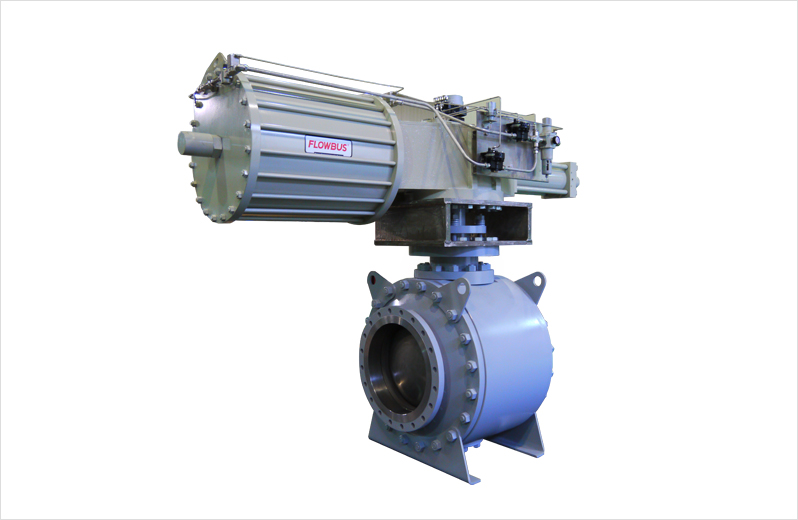

Metal Seated Ball Valve for Polysilicon Service

KD VALVE is available in Metal to Metal seated design for Poly-Silicon Industries.

The Scraper seat design and high hardness give the durability and the properties necessary to operate under severe conditions.

The valve ball is not easily damaged by MGSI powder, so it can give you best-in-class lifecycle.

Bidirectional sealing in addition to the scraper design will give the ultimate sealing to prolong the plant operation.

Our innovative technologies prevent damage from service fluid and erosion.

The valve also features Pocketless Design which eliminates the dead space that allows the powder to build up for a smooth valve operation and seat closure.

- Range : #150~#2500 / 1/2 inch~32 inch

- Standard : API, ANSI, ASME, DIN, User Spec, etc.

- Leakage Class : ANSI B16.104 (FCI 70-2) Class VI

- Valve Type : Forged, Side Split Body

- Case 3: KD VALVE’s innovations for Polysilicon plants mark a new milestone for the industry.

- Our own technologies have helped improve our clients’ production drastically. Before introducing our products, the products in the market were substandard, causing many faults and damages at the plant. For example, an inferior product has only one layer for the Stem packing, but KDVALVE has three-layer Multi Packing. Most of the other brands do not adopt live loading of stem packing but we provide it to maintain the integrity of the valve as well as protect materials from leaking. Our unique design features Zero-leakage as we have bi-directional sealing which will prevent powder from leaking to the spring unit. Innovative metallurgical technology helps us deliver best-in-class hardness to endure the harshest most severe conditions.