Metal Seated Ball Valve for High Abrasive and Erosion Service

KD VALVE is available in Metal to Metal seated design for Abrasive and Erosion Service, equipped with special designed scraper design seat and high hardness material. The valve ball and seat is of high hardness material, and is not easily damaged from the service fluid. Bidirectional sealing and the scraper seat design enable KD VALVE’s products to maintain the sealing and long-term operation. These are to prevent the damage from service fluid and erosion from inside passing.

- Range : #150~#2500 /1/2 inch~32 inch

- Standard : API, ANSI, ASME, DIN, User Spec, etc.

- Leakage Class : ANSI B16.104 (FCI 70-2) Class VI

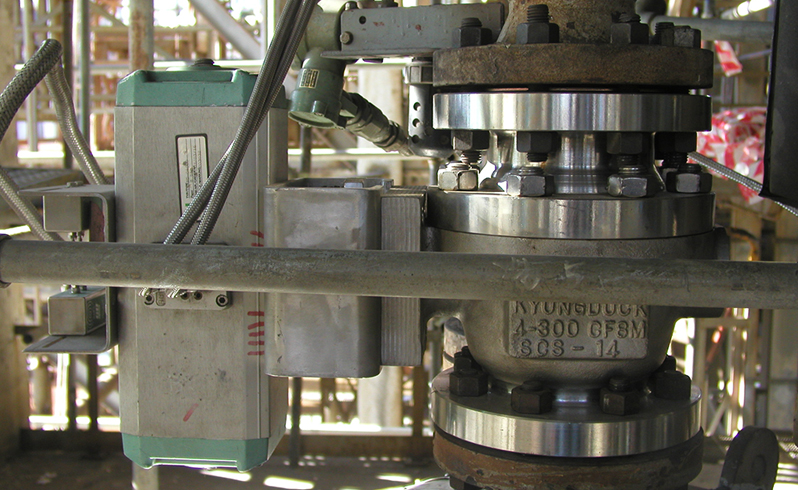

- Case 2: Improving the conditions of the slurry separators

- The slurry oil separator is used to reduce the solids of the oil. At our client’s RFCC unit, a certain brand had supplied metal-seated ball valves causing problems at site. It had serious sticking and leaking issues. The leakage was due to the worn-out stem and packing where the source of the leakage was from.

- After switching to KD VALVE products, the plant’s production was improved. It had no more sticking issues due to the capabilities of our manufacturing technologies. Zero leakage observed at 450℃ in the treated stem.